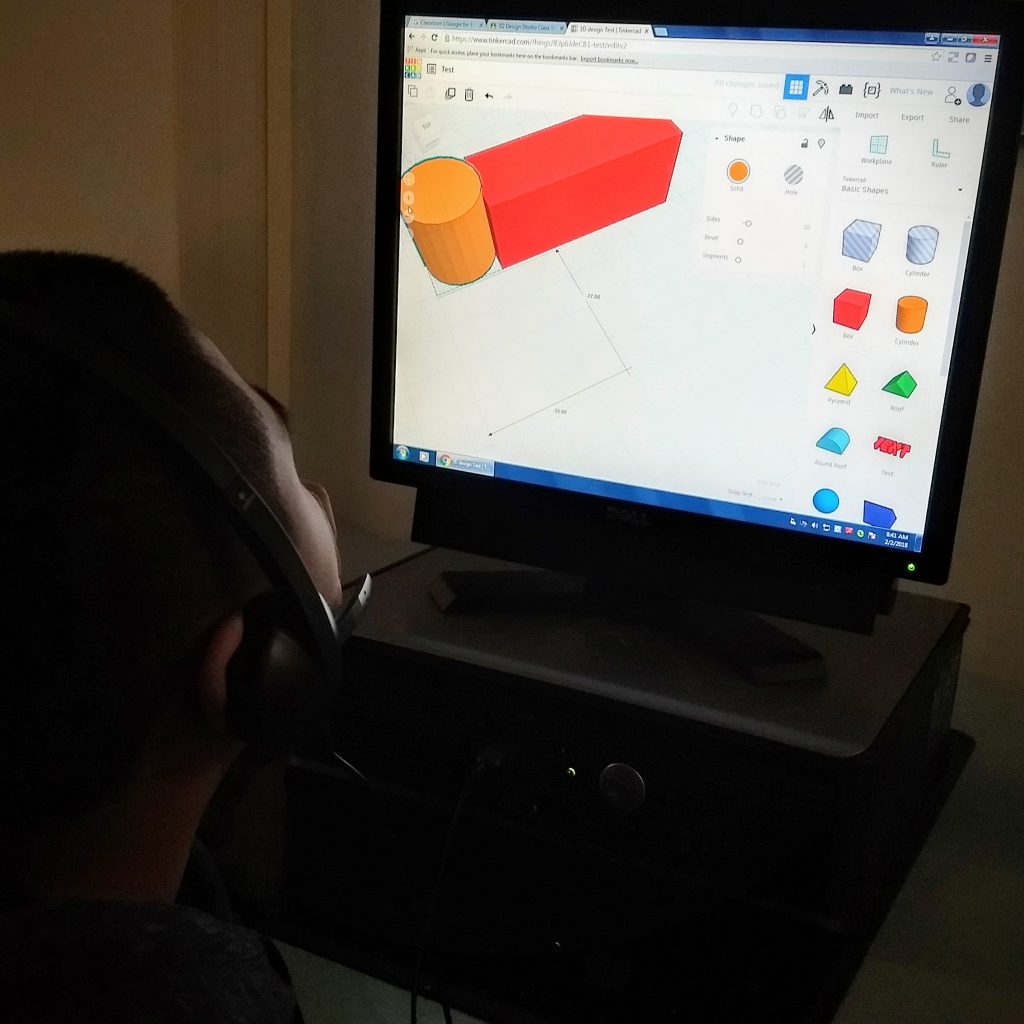

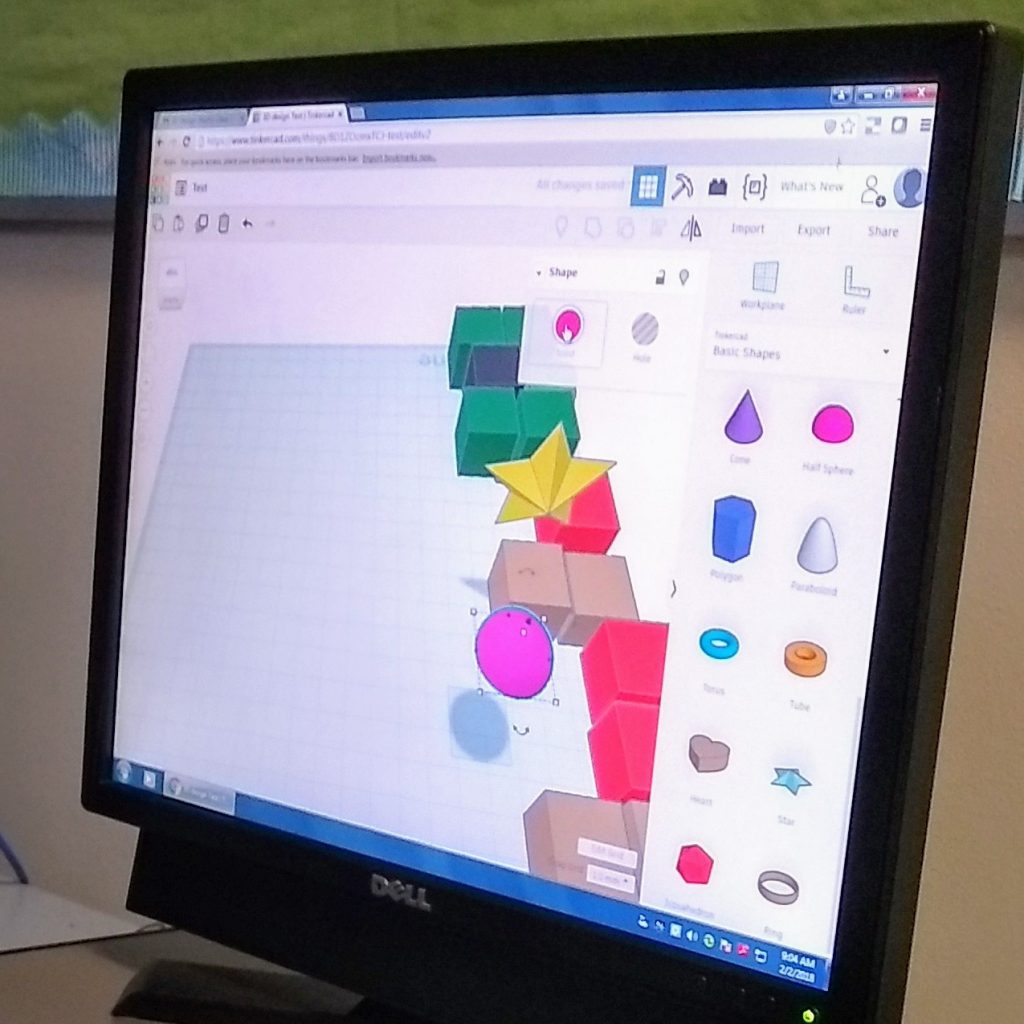

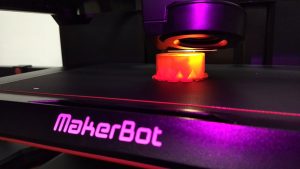

Over the past few weeks our 3D Studio students have been learning the basic tools and commands of Tinkercad. Their progress has been been a pleasant surprise, as digital natives the students come to my lab with many skills already in hand. Thanks to touch devices students understand zooming and rotating objects on screen. In addition I think video game experience plays a large part in the understanding of how to engage a 3D world and control a 3D camera. Hours of Mario and Madden Football have prepared them for this moment. All has not been easy as learning the intricacies of the software and how to effectively manipulate objects in exacting 0.05mm increments has been a bit of an uphill climb.

Now that the students have grown confident in design skills I have presented them with a challenge:

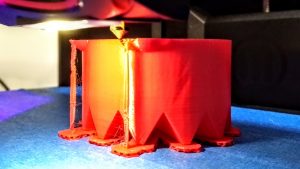

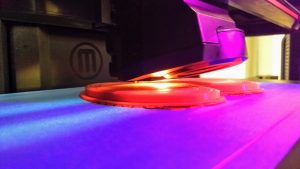

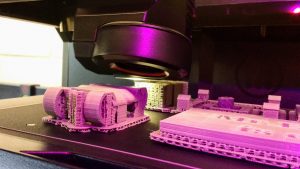

Design a 3D boat that can hold the most pennies possible before sinking.

To prepare for this challenge we took some time to learn about boats, what makes them float and how material and shape effect the design of a boat. After having a discussion about what the students thought made boats float we went to the YouTube (where else?) to learn more about boats and how they float:

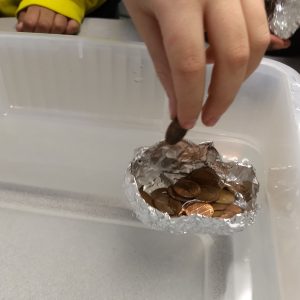

In order to test out the students newly acquired ship building knowledge we did an activity where they created boats out of aluminum foil. They first tested the sea worthiness of their boats and if they passed the test we loaded the boats with pennies until they sank. The boat that held the most was filled with 30 pennies before it sank!

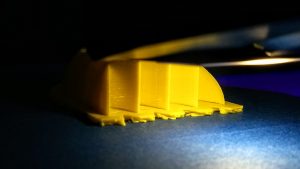

The students quickly realized that a flat bottomed boat displaced the water far better than a canoe or sailboat shaped design. Their ships would need to resemble cargo ships more so than a sleek racing boat.

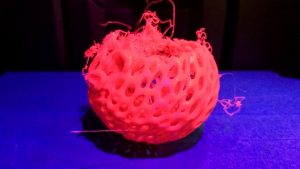

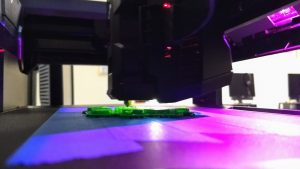

Our students have now developed 3D design skills, acquired some basic knowledge on floating boats, through trial and error built their own model ships and will now begin designing their own 3D printed boats. Will they be able to perform the 30 penny holding aluminium foil boat? We will see…

You must be logged in to post a comment.